Oxygen is one of the most vital industrial and medical gases, essential in both life-saving treatments and critical manufacturing processes. Traditionally, industries and hospitals have relied on bulk oxygen supply—delivered in cylinders or cryogenic liquid form. However, the growing demand for oxygen, coupled with supply chain challenges and the push for cost-effective, efficient operations, has sparked a major shift toward on-site oxygen generation.

In this blog, we’ll explore why on-site oxygen generation is transforming the healthcare and manufacturing sectors, the technologies involved, and how it delivers operational, economic, and safety advantages.

🔍 What is On-Site Oxygen Generation?

On-site oxygen generation involves producing oxygen gas directly at the point of use, eliminating the need for transportation and storage of cylinders or liquid oxygen tanks. This is achieved using two main technologies:

1️. PSA (Pressure Swing Adsorption) Technology

- How it works: PSA systems separate oxygen from atmospheric air by using molecular sieves that adsorb nitrogen under pressure, allowing oxygen to pass through.

- Oxygen Purity: Typically 90% to 95%

- Applications: Widely used in hospitals, metal cutting, glass manufacturing, ozone generation, and water treatment.

2️. VSA (Vacuum Swing Adsorption) and VPSA (Vacuum Pressure Swing Adsorption)

- How it works: Similar to PSA but uses a vacuum during the desorption cycle, improving energy efficiency for large-scale oxygen production.

- Best suited for: High-volume oxygen demands in steel, cement, and chemical plants.

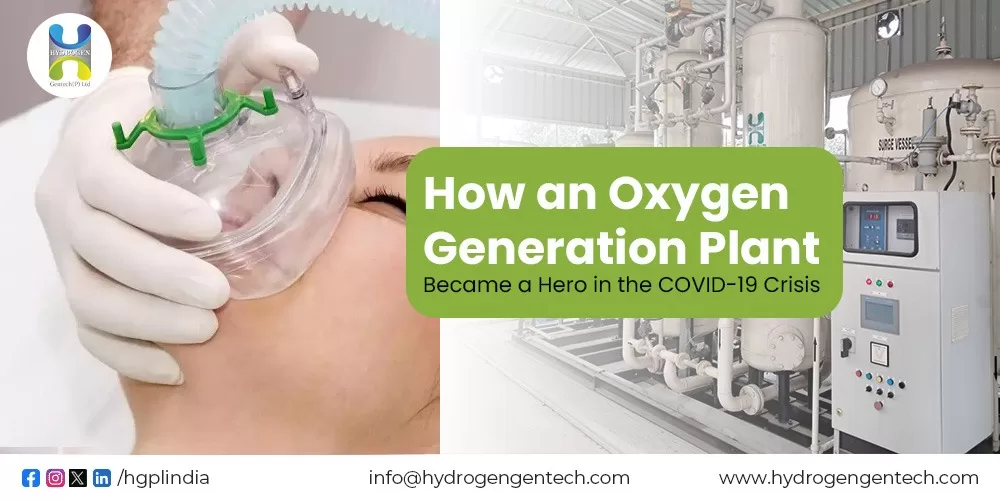

🏥 Why On-Site Oxygen is Crucial for the Healthcare Sector

✅ 1. Continuous, Reliable Oxygen Supply

In hospitals, oxygen is a life-critical gas used for:

- Respiratory support (ventilators, oxygen therapy)

- Surgical anesthesia

- Emergency treatment

- Intensive care and neonatal care

On-site generation ensures uninterrupted oxygen availability, which is especially critical during surges in demand—as witnessed during the COVID-19 pandemic.

⚠ During global emergencies, supply chains often collapse. On-site oxygen plants eliminate this risk by enabling hospitals to be self-reliant.

✅ 2. Cost Savings

Hospitals can significantly reduce recurring expenses:

- No more bulk oxygen purchases

- Elimination of cylinder logistics and handling costs

- Reduced labor and inventory management

✅ 3. Enhanced Safety

Cylinders and liquid oxygen storage pose fire and explosion risks. On-site systems produce oxygen as needed, minimizing stored volumes and reducing hazards.

✅ 4. Scalability and Automation

Modern on-site oxygen plants, like HGPL’s PSA-based systems, come with automated controls, remote monitoring, and easy scalability. Hospitals can start small and expand as needed.

🏭 On-Site Oxygen in Manufacturing: Driving Efficiency & Performance

In the industrial world, oxygen is a process-enhancing gas used to improve combustion efficiency, increase reaction rates, and maintain product quality. Here’s how on-site generation transforms manufacturing operations:

✅ 1. Enhanced Process Efficiency

- Metal cutting and welding: Higher oxygen purity improves flame temperature and cut quality.

- Glass and ceramics: Oxygen boosts combustion temperatures, improving melting efficiency and product uniformity.

- Water treatment: Oxygen supports ozone generation and aerobic digestion processes.

✅ 2. Reduced Operating Costs

- Avoid cylinder rental, delivery charges, and wastage from unused gas in cylinders.

- Lower energy consumption per Nm³ compared to liquefied oxygen.

💡 Many industries experience 30–60% savings in oxygen-related costs after switching to on-site generation.

✅ 3. Reliable Oxygen Supply

- Eliminate supply chain dependencies and production downtime due to delivery delays or oxygen shortages.

- Continuous oxygen supply aligns with just-in-time manufacturing practices.

✅ 4. Custom Purity & Flow Rates

- PSA oxygen systems can be tailored to deliver exact purity and flow rates needed for specific processes.

- Avoid overpaying for ultra-high purity oxygen when standard purity suffices.

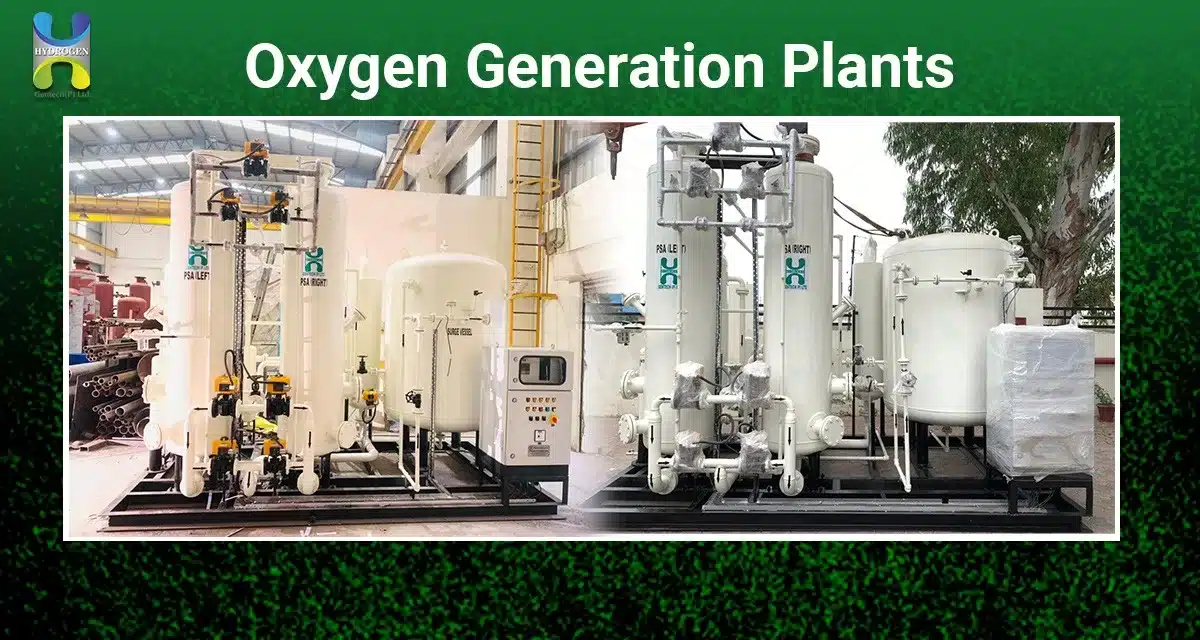

🔬 Key Technical Features of HGPL’s On-Site Oxygen Generators

At Hydrogen Gentech Private Limited (HGPL), we engineer advanced PSA oxygen generators for both healthcare and industrial applications. Key features include:

🔹 High-Efficiency Molecular Sieves

Ensures consistent oxygen purity (90%–95%) with minimal degradation over time.

🔹 Energy-Efficient Design

Low specific power consumption (kWh/Nm³ of oxygen) using optimized cycle timing and advanced control systems.

🔹 Touchscreen PLC Control Panel

Automated system with alarms, real-time oxygen purity display, and data logging.

🔹 Modular and Scalable

Easy to expand or relocate based on demand changes.

🔹 Medical-Grade Compliance

Meets standards for medical oxygen use, including filtration and dew point control.

🧾 Comparison: On-Site Oxygen vs. Liquid/Cylinder Supply

| Feature | On-Site Generation | Cylinder Supply | Liquid Oxygen |

| Cost Efficiency | High | Low | Moderate |

| Purity Range | 90–95% | 99% | 99% |

| Supply Reliability | Continuous | Prone to delays | Prone to supply chain issues |

| Safety | High | Moderate risk (pressurized) | High risk (cryogenic) |

| Storage Needs | Minimal | High | Very High |

| Automation | Fully automated | Manual | Manual filling |

💼 Industries Benefiting from On-Site Oxygen Generation

- Healthcare (Hospitals, Clinics, Emergency Response Centers)

- Metal Fabrication (Cutting, Welding, Brazing)

- Glass and Ceramics Manufacturing

- Wastewater Treatment Plants

- Pulp and Paper Industry

- Ozone Generation Systems

- Fish Farming (Aquaculture)

✅ The Shift Toward On-Site Oxygen is Inevitable

On-site oxygen generation is no longer just an alternative—it’s fast becoming the standard in both healthcare and manufacturing. It delivers unmatched operational control, cost savings, and safety, while supporting sustainability and reliability in oxygen-critical applications.

🚀 Whether you’re running a hospital or a high-precision manufacturing unit, on-site oxygen generation empowers your operations to be more agile, efficient, and future-ready.

📩 Interested in upgrading to an on-site oxygen solution?

Connect with HGPL today to explore our range of PSA Oxygen Generators designed for your specific needs—engineered for reliability, built for performance.

EMAIL: info@hydrogengentech.com MOB: +91-9818 744 776