Green hydrogen is emerging as a cornerstone in the global transition to clean and sustainable energy. This revolutionary approach offers an unparalleled opportunity for India to lead the way in the hydrogen economy and achieve its ambitious climate goals. In this blog post, we will explore the role of green hydrogen in India’s energy landscape and discuss how it can reshape the country’s energy paradigm.

Understanding Green Hydrogen

Green hydrogen is produced through water electrolysis using renewable energy sources such as solar and wind power. This process is entirely carbon-free, making green hydrogen a clean and sustainable alternative to traditional fossil fuels. As a versatile energy carrier, green hydrogen can be used in various sectors including transportation, industry, and power generation.

India’s Energy Landscape

India’s energy demand is expected to grow rapidly in the coming years, driven by economic growth and urbanization. Traditionally, the country has relied heavily on fossil fuels such as coal and oil to meet its energy needs. However, this approach has led to significant environmental challenges, including air pollution and greenhouse gas emissions.

To address these challenges, India has set ambitious targets for renewable energy generation, aiming to achieve 450 GW of renewable capacity by 2030. Green hydrogen can play a pivotal role in achieving these goals by providing a clean, sustainable, and versatile energy source.

Advantages of Green Hydrogen

- Decarbonization: Green hydrogen can significantly reduce carbon emissions in key sectors such as transportation and industry.

- Energy Security: By utilizing local renewable resources, India can reduce its dependence on imported fossil fuels and enhance its energy security.

- Economic Growth: The development of a green hydrogen economy can create new jobs and stimulate economic growth in the renewable energy sector.

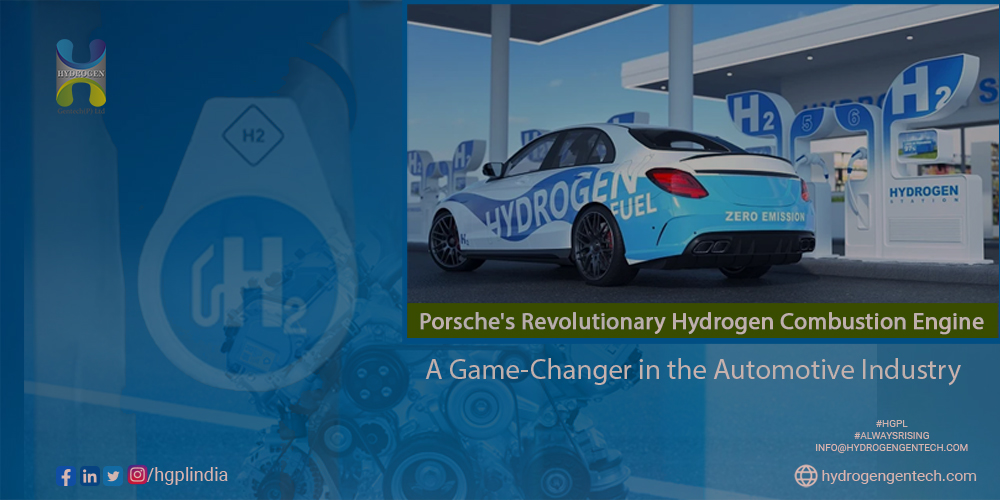

- Technological Innovation: Green hydrogen technologies offer opportunities for innovation in water electrolysis, storage, and distribution systems.

Applications of Green Hydrogen

- Power Generation: Green hydrogen can be used to produce electricity, providing a clean and reliable energy source.

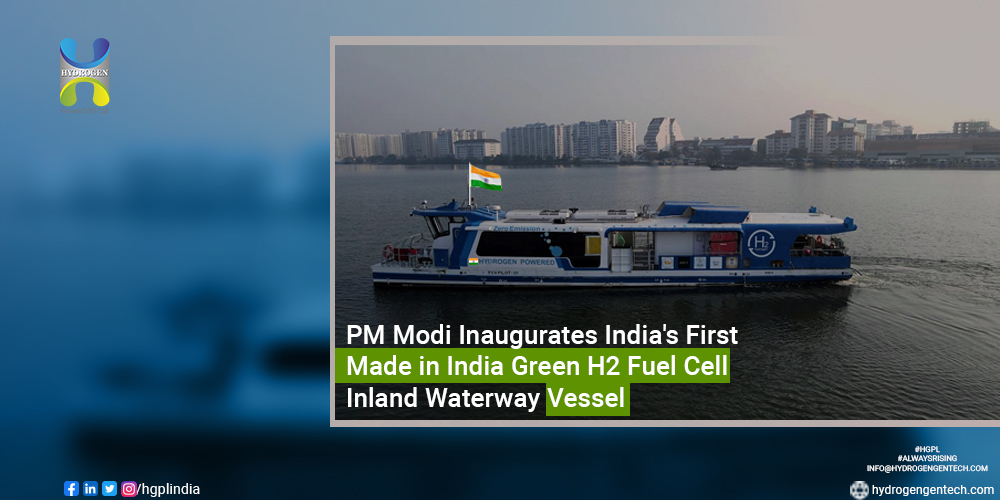

- Transportation: Hydrogen fuel cells can power vehicles such as cars, buses, and trucks, offering an emissions-free alternative to traditional fuels.

- Industrial Processes: Green hydrogen can be used in industrial processes such as steel and cement production, reducing their carbon footprint.

- Energy Storage: Hydrogen can store excess renewable energy, providing a flexible and reliable energy storage solution.

India’s Green Hydrogen Initiatives

India has recognized the potential of green hydrogen and has taken several initiatives to promote its development:

- National Hydrogen Mission: Launched in 2021, this mission aims to promote the production and use of green hydrogen in India.

- Collaborations: India has partnered with international organizations and countries to develop hydrogen technologies and infrastructure.

- Investment and Incentives: The government is providing financial incentives and support to encourage investment in green hydrogen projects.

Challenges and Future Outlook

While green hydrogen holds immense promise, there are challenges that need to be addressed:

- Cost: The cost of producing green hydrogen is currently higher than that of traditional fuels. However, as technology advances and economies of scale are achieved, the cost is expected to decrease.

- Infrastructure: Developing the necessary infrastructure for hydrogen production, storage, and distribution requires significant investment.

- Policy and Regulation: Clear and supportive policies and regulations are essential to facilitate the growth of the green hydrogen industry.

The future of green hydrogen in India looks promising. As the country continues to invest in renewable energy and hydrogen technologies, it can lead the way in the global hydrogen economy. By embracing green hydrogen, India can unleash a new energy paradigm that supports sustainable development and helps combat climate change.