Hydrogen Generation Plants

Introduction

Hydrogen generation plants are critical in meeting the growing demand for clean energy sources. There are several technologies used in these plants to produce hydrogen, including water electrolysis, methanol cracking, and steam methane reforming.

Water electrolysis is a process that uses an electrical current to split water molecules into hydrogen and oxygen gases. This method is highly efficient and produces pure hydrogen from a renewable source that is water, but it requires significant amounts of energy.

Methanol cracking involves heating methanol to high temperatures to produce hydrogen and carbon monoxide /carbon dioxide gases. This method can use sources of methanol, making it a more sustainable option.

Steam methane reforming involves reacting natural gas with steam at high temperature to produce hydrogen and carbon dioxide gases. This method is the most commonly used industrial process for large capacity of hydrogen production due to its high efficiency and low cost.

Industrial hydrogen generation plants are typically large-scale operations, capable of producing hundreds of tons of hydrogen per day.

The produced hydrogen can be used in a variety of applications, including fuel cells, hydrogenation of oils, and production of ammonia. However, the production of hydrogen still requires significant amounts of energy, and the source of that energy can greatly impact the environmental benefits of using hydrogen as a fuel.

Hydrogen Gentech Private Limited (HGPL)’s research and development efforts continue to focus on increasing the efficiency and reducing the environmental impact of Hydrogen generation plants.

Hydrogen Gentech Private Limited (HGPL) offers Hydrogen Generation Plants through various technologies on EPC / Turnkey Basis.

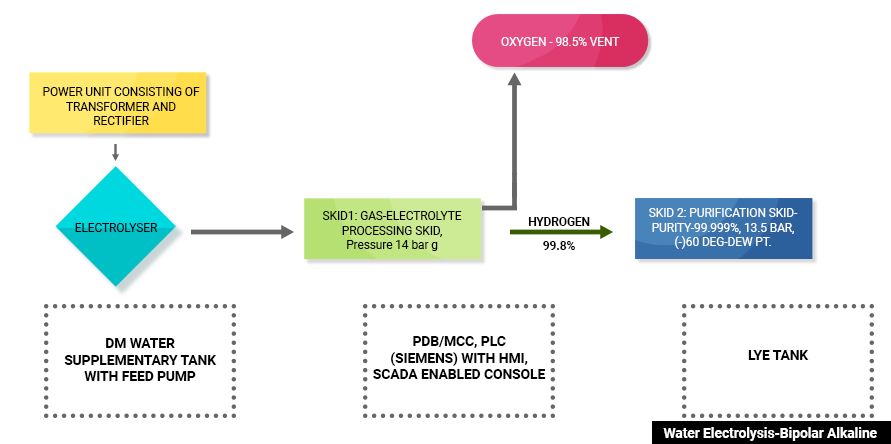

- Water Electrolysis-Bipolar Alkaline

- Under this process, an electrolyser solution is split using electricity to liberate Hydrogen & Oxygen.

- This splitting with the help of electricity is known as the WATER ELECTROLYSIS PROCESS.

- We undertake Hydrogen generation plants projects on an EPC Basis based on sourcing H2 Electrolyser stacks from reputed International manufacturers, while balance of plant units are manufactured and supplied by us.

- Being modular in nature, these plants can be configured for a wide capacity and flow range of 2 – 500 Nm3/h.

- A basic Hydrogen will consist of a Power Control Unit, Bipolar cell stacks, Hydrogen Generation and Purification units with PLC-based Control panel & SCADA System for ensuring safety and fully automatic operations while meeting international standards.

- Hydrogen delivered with ultra-high purity – 99.999% and at high pressure of 13-15 bar g.

- Ensuring guaranteed electrolyzer life of a minimum of 07 years.

- All Equipment & components are manufactured or procured from world-class reputable suppliers.

Guaranteed Parameters:

| S.NO | COMPONENT | UNIT | SPECIFICATIONS |

| 1 | HYDROGEN PURITY AFTER ELECTROLYZER | % by Volume | 99.8 |

| 2 | OXYGEN PURITY AFTER ELECTROLYZER | % by Volume | 98.5 |

| 3 | HYDROGEN PURITY AFTER PURIFICATION UNIT | % by Volume | 99.999 |

| 4 | DEW POINT (BETTER THAN) | (-) 60 | |

| 5 | MINIMUM DELIVERY PRESSURE AFTER PURIFICATION UNIT | Bar (g) | 13 |

| 6 | DM WATER REQUIRED TO PRODUCE PER NM3 OF HYDROGEN GAS | Litre | 0.9 |

| 7 | AC POWER CONSUMED TO PRODUCE PER NM3 OF HYDROGEN GAS | KWh | 5 (Max) |

Process Flow:

Applications of Hydrogen Gas

Steel & Metal Processing

It is often used in annealing stainless-steel alloys, magnetic steel alloys, sintering and copper brazing.

Hydrogen gas also acts as a reducing agent in processing metallic ores, an important application in metallurgy and industries requiring pure metals.

Hydrogen is mixed with inert gases to obtain a reducing atmosphere, which is required for many applications in the metallurgical industry, such as heat-treating steel and welding.

Hydrogen gas also acts as a bonding agent in the process of Galvanizing, which also gives steel its shiny nature.

Food & Drugs

Hydrogen is used in the Pharmaceutical Drug industry for various reactions. Hydrogen, being the lightest element, is capable of forming a single bond easily with any element.

Hence each chain of Organic or Inorganic chemicals can take various forms when reacted with Hydrogen by forming different chains and bonds.

Edible Oils

The largest scale application of hydrogen is HYDROGENATION. The hydrogenation process converts the unsaturated oil into saturated oil.

The purpose is to raise the melting point, increase the oxidation and heat stability of the oil. This process also improves the color, taste, and flavor of the oil.

Typical vegetable oils are derived from polyunsaturated fatty acids (containing more than one carbon-carbon double bonds). Their partial hydrogenation reduces most but not all, of these carbon-carbon double bonds.

These hardened fats are then used generally in combination for the formulation and processing of vegetable ghee (vanaspati).

Chemicals & Pharmaceuticals

Hydrogen is used in large quantities as a raw material in the chemical synthesis of various chemicals of industrial use…like ammonia, hydrochloric acid, methanol, hydrogen peroxide, polymers, and solvents.

In Pharmaceuticals, Hydrogen is mainly used in Hydrogenation reaction for many products, besides other applications.

Hydrogenation is also followed in the chemical industry in order to get various new chemicals (organic and inorganic).

Hydrocarbons chain is altered by the addition of Hydrogen, hence giving rise to different types of chemicals.

Refinery & Petrochemical

In refineries, it is used to remove the sulfur that is contained in crude oil as well as to convert heavy crude to lighter, easier to refine, and more marketable products.

The petrochemical industry uses hydrogen gas to process common fossil fuels, upgrading them to purer forms.

Petrochemical methods involving hydrogen include hydrodesulphurization, hydro cracking, and hydrodealkylation.

Float Glass

In order to allow the irregularities in the glass to even out, the glass is held in a controlled atmosphere with a ratio of approximately 90% N2 : 10% H2.

To produce sheets of flawless glazing for windows, doors, etc., a continuous ribbon of glass is “floated” on a bed of tin. The hydrogen in the controlled atmosphere acts as a scavenging agent to ensure an oxygen-free environment, since molten tin is highly sensitive to oxidation.

Power Industry

Being the lightest gas, it has good dispersing properties. Hence it is used for turbine cooling in power generators.

Hydrogen is being considered as a replacement for today’s fossil fuels because it is abundant, efficient, and unlike other alternatives, it offers the potential to be renewable, and it produces no emissions.

It can be utilized as the energy carrier for generating electrical power with hydrogen fuel cells and hydrogen combustion engines.

Many fuel cells utilized today for distributed power generation require integration with a fuel processor to produce a hydrogen-rich gas from a hydrocarbon-based fuel such as natural gas or propane.

Electronics and Semi-Conductors

Hydrogen is used as carrier gas in semiconductor processes, especially for silicon deposition or crystal growing.

And as a scavenger gas in atmosphere, soldering as well as for annealing copper films.

The use of forming gases (that is H2 diluted in nitrogen) allows virtually a complete elimination of oxygen and its inconveniences in medium to high temperature processes.

Meteorology

In meteorological applications, hydrogen is used as a lift gas where helium is unavailable or prohibitively expensive.

Solar & New Energy Sources

Mobility: FCEV (Fuel Cell Electric Vehicles)

Hydrogen is now considered as the next generation source of energy and clean. Hydrogen Fuel Cell electric Vehicles (Cars, Buses, Trucks, ships, trains) use compressed Hydrogen Gas with oxygen from air to generate electrical power for the engine while emitting only pure water. Hydrogen in mobility applications is being considered as a superior long-term alternative to battery-powered vehicles in case its cost of generation is optimized and hydrogen fueling infrastructure and transportation are established in an efficient manner in the near future.

SOLAR:

Used in solar manufacturing for cutting and edging out of rough surfaces on the cells.