Nitrogen/Oxygen Gas Plants

Introduction

Nitrogen & Oxygen Generation Plants are industrial facilities designed to produce these gases in large quantities for various applications. The process typically involves separating these gases from the air.

Hydrogen Gentech Private Limited (HGPL) offers Nitrogen Generation Plant based on PSA – Pressure Swing Adsorption Technology and Oxygen Generation Plant based on both PSA – Pressure Swing Adsorption & VPSA – Vacuum Pressure Swing Adsorption Technology.

Nitrogen & Oxygen Generation plants based PSA and VPSA technology offer many benefits, including high purity levels, low operating costs, and minimal environmental impact. These plants can be customized to meet specific production requirements and can be easily integrated into existing production processes.

The Promoters of Hydrogen Gentech Private Limited (HGPL) holds expertise and experience of more than 25 years in the designing & manufacturing Nitrogen & Oxygen Generation Plants through PSA technology.

Hydrogen Gentech Private Limited (HGPL) offers Nitrogen & Oxygen Plants on EPC / Turnkey Basis.

- NITROGEN GENERATION UNIT

- OXYGEN GENERATION PLANTS

Hydrogen Gentech Private Limited (HGPL) Manufactures ON-SITE PSA Nitrogen Generation Plants.

Under this technology, the Nitrogen is produced from air by removing the Oxygen through adsorption process.

Nitrogen Generation Plant based PSA technology offer many benefits, including high purity levels, low operating costs, and minimal environmental impact. These plants can be customized to meet specific production requirements and can be easily integrated into existing production processes.

Various models suitable for producing commercial nitrogen and ultra-pure nitrogen are available.

Gas produced by the plant is very economical as compared to cylinder / liquid nitrogen.

Moisture levels as low as dew point (-)90 deg Celsius can be achieved through our Nitrogen processing units.

HGPL Offers Below Given Nitrogen Generation Plant Models:

1. Nitrogen RP

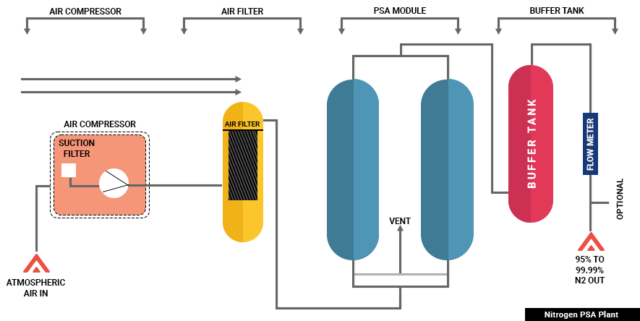

First and basic model for producing Nitrogen Gas which requires only compressed air to produce Nitrogen Gas at a desired flow. Nitrogen is produced by PSA (Pressure Swing Adsorption) technology in the bed filled with molecular sieve.

This is a twin tower system. Where one tower is in adsorption mode, other one is in re-generation mode hence ensuring continuous operations.

Carbon Molecular Sieve – CMS used in PSA system is from Carbotech-AcGmBH.

Purity achieved from this unit is 99% (vol.).

Guaranteed Parameters:

| S.NO | COMPONENT | UNIT | PARAMETER |

| 1 | FLOW | nm3/h | 1-1500 |

| 2 | NITROGEN GAS PURITY | % vol | 96-99 |

| 3 | DELIVERY PRESSURE | bar (g) | 7-20 |

| 4 | DELIVERY TEMPERATURE | Deg celcius | Ambient |

| 5 | DEW POINT | Deg celcius | (-) 40 to (-)60 |

| 6 | TRACE OXYGEN | % vol | 4 to 0.1 |

| 7 | TRACE HYDROGEN | % vol | NIL |

Process Flow:

2. Nitrogen HP

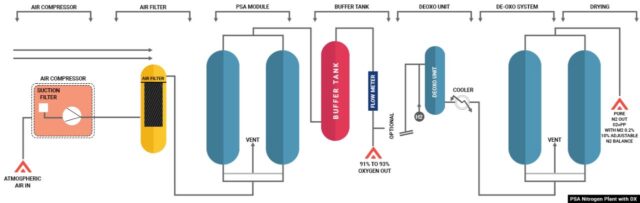

High Purity Nitrogen HP-Model is offered by HGPL in the field of NITROGEN GENERATION PROCESS by reducing oxygen(impurity) content as low as it can i.e. below 5 ppm.

A PSA system (as in NITROGEN LP-model) is followed by additional purification unit using palladium as catalyst for removal of oxygen & moisture contents upto 1 PPM level.

The De-oxidation unit is a reactor bed filled with Palladium Catalyst.

The Nitrogen, coming directly from the PSA System with the remaining Oxygen, is mixed with Hydrogen before entering the catalyst reactor.

At the catalyst surface the oxygen reacts with Hydrogen to produce water and heat.

The heat and water have to be removed by a standard water separator after cooler and gas dryer to required level.

The remaining hydrogen concentration in the Nitrogen is around 0.5 to 1% minimum.

The high purity HP-Model finds application in chemical/electronics/ metallurgical industries.

Maximum purity achieved from this unit is 99.99% (vol.).

Carbon Molecular Sieve – CMS used in PSA system is from Carbotech-AcGmBH.

Guaranteed Parameters:

| S.NO | COMPONENT | UNIT | PARAMETER |

| 1 | FLOW | nm3/h | 1-1500 |

| 2 | NITROGEN GAS PURITY | % vol | 99.995 |

| 3 | DELIVERY PRESSURE | bar (g) | 5-20 |

| 4 | DELIVERY TEMPERATURE | Deg celcius | ambient |

| 5 | DEW POINT | Deg celcius | (-) 60 to (-)80 |

| 6 | TRACE OXYGEN | PPM | 5 |

| 7 | TRACE HYDROGEN | % vol | 0.5 – 1 |

Process Flow:

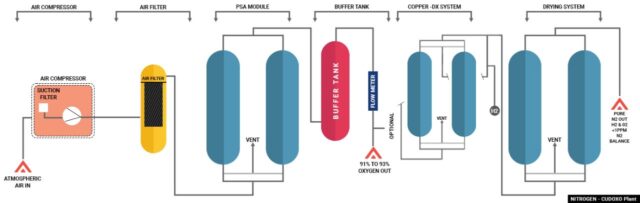

3. Nitrogen UHPr

High Purity Nitrogen HP-Model is offered by HGPL.

In this model, different type of DE-Oxidation unit is used for additional cleaning using.

copper catalyst is used for removal of extra Oxygen, the moisture and Hydrogen contents are maintained upto 1PPM level.

This Ultra-pure nitrogen gas finds application in electronic, synthetic fibre and optical fibre industries. These systems are installed where along with Oxygen & Moisture, Hydrogen is not desired in the Nitrogen gas Stream.

This DE-Oxidation unit consists of two externally heated and filled columns with copper as catalyst for the endothermic reaction.

The loaded copper bed can be regenerated by adding Hydrogen during the regeneration step.

For this two-step process (Deoxidization and regeneration), two reactors are necessary to achieve a continuously operating DE-OXO system.

The nitrogen from the PSA System with the remaining oxygen passes over one of the reactors without adding Hydrogen. On passing through the reactor, the oxygen is removed by reacting with the copper surface.

The advantage of the DE-OXO unit based on the copper is that the high purity nitrogen leaves the unit absolutely dry & without any remaining Hydrogen.

Maximum purity achieved from this unit is 99.9999% (vol.).

Carbon Molecular Sieve – CMS used in PSA system is from Carbotech-Ac GmBH.

Guaranteed Parameters:

| S.NO | COMPONENT | UNIT | PARAMETER |

| 1 | FLOW | nm3/h | 1-1500 |

| 2 | NITROGEN GAS PURITY | % vol | 99.9999 |

| 3 | DELIVERY PRESSURE | bar (g) | 7-20 |

| 4 | DELIVERY TEMPERATURE | Deg celcius | Ambient |

| 5 | DEW POINT | Deg celcius | (-) 60 to (-)80 |

| 6 | TRACE OXYGEN | PPM | 1 |

| 7 | TRACE HYDROGEN | % vol | NIL |

Process Flow:

Applications of Nitrogen Gas

Steel & Metal Processing

It is often used in annealing stainless-steel alloys, magnetic steel alloys, sintering and copper brazing.

Nitrogen gas also acts as a reducing agent in processing metallic ores, an important application in metallurgy and industries requiring pure metals.

Nitrogen is mixed with Hydrogen, mixture known as HNX to obtain a reducing atmosphere, which is required for many applications in the metallurgical industry, such as heat treating steel and welding.

Float Glass

In order to allow the irregularities in the glass to even out, the glass is held in a controlled atmosphere with a ratio of approximately 90% N2; : 10% H2.

To produce sheets of flawless glazing for windows, doors, etc., a continuous ribbon of glass is “floated” on a bed of tin. The hydrogen in the controlled atmosphere acts as a scavenging agent to ensure an oxygen-free environment, since molten tin is highly sensitive to oxidation.

Food Packaging & FMCG Industry

Being inert in nature (unlike Oxygen and Air), Nitrogen is used to preserve food items by keeping Oxygen and Moisture away.

When compressed, it is also used for pneumatic operations in the industrial machinery.

Emergency and Purging Applications

Being an inert gas and having the ability to freeze, Nitrogen is used for emergency flushing in case of fires.

Also, nitrogen is used to flush any system or plant machinery pre and post startup and shutdown respectively.

Gas Blanketing

A critical nitrogen gas application is the blanketing of storage tanks for volatile chemical compounds.

HGPL manufactures and supplies on-site Oxygen Generators based on PSA (Pressure-Swing-Adsorption) and VPSA (Vacuum-Pressure-Swing-Adsorption) technology.

The oxygen generation process involves the use of specialized equipment, including air compressors, air filters, air dryers, and molecular sieve adsorbers. The compressed air is then passed through a series of filters to remove impurities, such as water vapor, carbon dioxide, and other contaminants. Once the air is purified, it is then passed through a molecular sieve adsorber, which separates oxygen from the air.

Oxygen is generated directly from air at less than one third cost of Oxygen from cylinders.

Flow can be achieved from 1-300 Nm3/hr.

Maximum purity of upto 90-94% (vol.).

HGPL offers PSA & VPSA based Oxygen Generation Plants

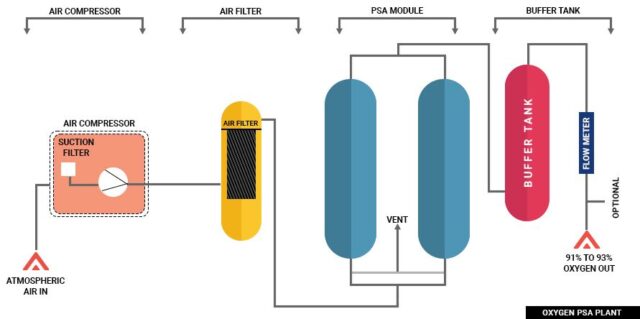

1. PSA Based Oxygen Generation Plant

Compressed Air from Air Compressor is passed through a filtration unit to remove the moisture and dust particles.

Main adsorption system consists of two adsorbers with synthetic Zeolite (Molecular Sieve) inter-connected through changeover valves.

At a time one adsorber remains in adsorption and generate the Oxygen, while the second is regenerated by purging.

Oxygen purity and pressure fluctuates at the outlet of adsorber. Hence a surge vessel is provided for stabilizing the same. Oxygen comes out from surge vessel with stable purity & pressure.

Oxygen Purity obtained from PSA shall be around 91-93 %. This purity is acceptable in most of the applications.

Guaranteed Parameters:

| S.NO | COMPONENT | UNIT | PARAMETER |

| 1 | FLOW | nm3/h | 1-1000 |

| 2 | OXYGEN GAS PURITY | % vol | 91-93 |

| BALANCE COMPONENT | Nitrogen & Argon | ||

| 3 | DELIVERY PRESSURE | bar (g) | 2-3 |

| 4 | DELIVERY TEMPERATURE | Deg celcius | ambient |

| 5 | DEW POINT | Deg celcius | (-) 40 |

Process Flow:

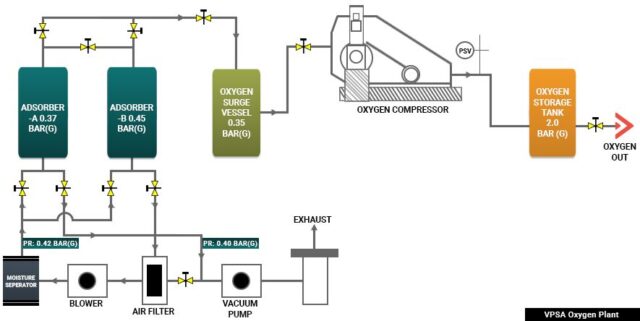

2. VPSA Based Oxygen Generation Plant

In this process, Air from a Blower is first cooled in an Aftercooler to reduce its moisture content and condensed moisture is separated in Moisture Separator.

The cooled air passes through a Tower containing an adsorbent which has the property to separate Oxygen from the air resulting in a gas contains 93% Oxygen (balance being Argon & Nitrogen) coming out as product gas.

To ensure continuous flow of product gas, the other Tower is simultaneously regenerated by extracting the gases adsorbed in the previous cycle by a Vacuum Pump.

Automatic operation is achieved by opening & closing the valves in a pre-set sequence by using a PLC.

The Oxygen product flow is compressed to the required discharge pressure, if required and fed to end use process.

Power efficient systems with Flow achievable from 500-5000 Nm3/hr.

The waste gas is 80-85% Nitrogen and 11-15% Oxygen which is vented to atmosphere via discharge silencer.

Guaranteed Parameters:

| S.NO | COMPONENT | UNIT | PARAMETER |

| 1 | FLOW | nm3/h | 500-5000 |

| 2 | OXYGEN GAS PURITY | % vol | 91-94 |

| 3 | DELIVERY PRESSURE (without compressor) | bar (g) | 0.25 – 0.5 |

| 4 | DELIVERY TEMPERATURE | Deg celcius | ambient |

| 5 | DEW POINT | Deg celcius | (-) 40 |

| 6 | TRACE COMPONENTS | Nitrogen & Argon |

Process Flow:

Applications of Oxygen Gas

Steel Industry

Oxygen is a key component in the production of steel. Oxygen is used in the steelmaking process to increase the efficiency of blast furnaces, and it is also used to enhance the combustion of fuels in the electric arc furnace.

Chemical Industry

In the chemical industry, oxygen is used as a reactant in various chemical reactions. Oxygen is also used to increase the efficiency of combustion processes in various chemical production facilities.

Pharmaceutical Industry

Oxygen is used in the pharmaceutical industry for the production of certain drugs and chemicals. Oxygen is also used in the sterilization of medical equipment and in the treatment of patients with respiratory problems.

Petroleum Industry

Oxygen is used in the petroleum industry for the production of gasoline, diesel fuel, and other petroleum products. Oxygen is also used in the refining process to improve the quality of the final products.

Mining Industry

In the mining industry, oxygen is used to enhance the efficiency of blast furnaces and to increase the rate of chemical reactions. Oxygen is also used to treat wastewater in mining operations.

Aerospace Industry

Oxygen is used in the aerospace industry to power rocket engines and to supply breathable air to pilots and passengers in airplanes.

Food Industry

Oxygen is used in the food industry for the preservation of food products. Oxygen is also used in the packaging of certain foods to extend their shelf life.

Glass Industry

Oxygen is used in the glass industry for the production of certain types of glass. Oxygen is also used to enhance the combustion of fuels in glass furnaces.

Environmental Industry

Oxygen is used in the environmental industry for the treatment of wastewater and for the remediation of contaminated soils and groundwater.